With nearly 160 years of experience in product innovation and state-of-the-art manufacturing processes, ARaymond has become one of the world’s foremost assembly solution experts. Drawing upon decades of experience leading the automotive fastening and assembly market, ARaymond is now working to help industrialize the construction industry with products designed for automation, sustainability and improved productivity.

At ARaymond, our actions are guided by the desire for a sustainable future, one that is respectful of people and the planet. It is our hope that through collaboration and the adoption of new technologies and innovations that we can work together to help alleviate the global housing crisis.

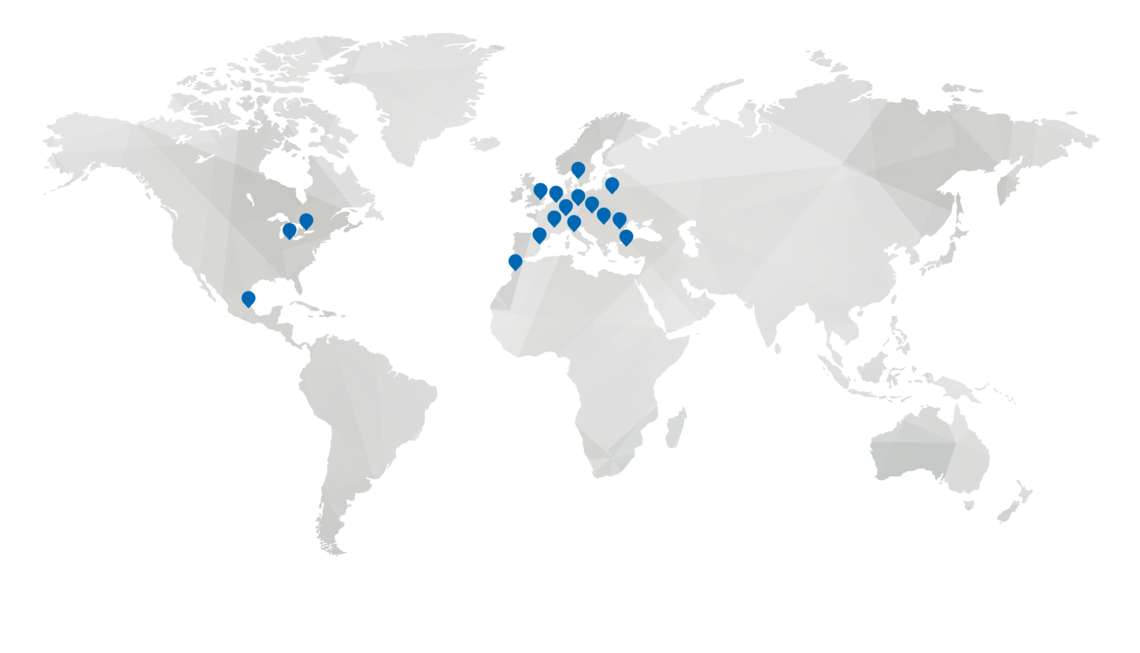

State-of-the-art Facilities

Through the design of innovative fastening and assembly systems, complex multi-material parts and the equipment required to produce them, ARaymond has earned a solid reputation for quality. In the production field, our expertise covers every stage in the development cycle of new products, from prototyping to mass production. We can therefore guarantee quality, cost and delivery times.

Metal transformation

We are fully conversant with the main metal transformation processes (cutting, bending, stamping and roll-forming), and can provide single or multi-layer heat treatments, including surface treatments.

Plastic injection

ARaymond's plastic capabilities include injection molding, over-molding and bi-injection (multi-materials) processes with a choice of over 300 thermoplastic materials and presses as large as 1000 tons / 128-cavity molds.

Assembly

Our manufacturing plants can manage manual, semi-automated or automated assembly, which can be optimized according to the production cycle, and also high-frequency assembly, at rates of up to 24,000 parts per hour.

Building industry associations

ARaymond has an active role in the following building industry associations.

A team and all its expertise at your service